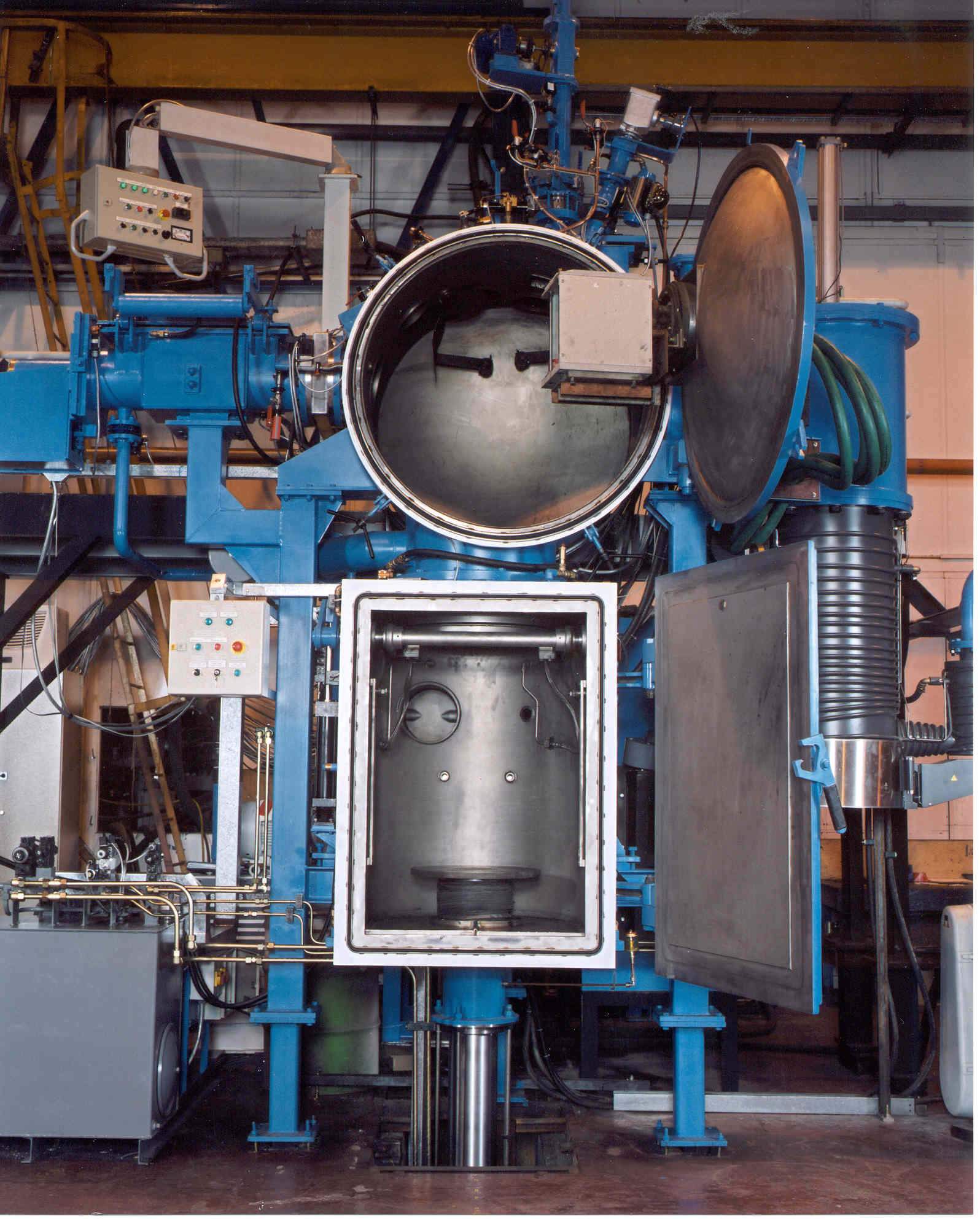

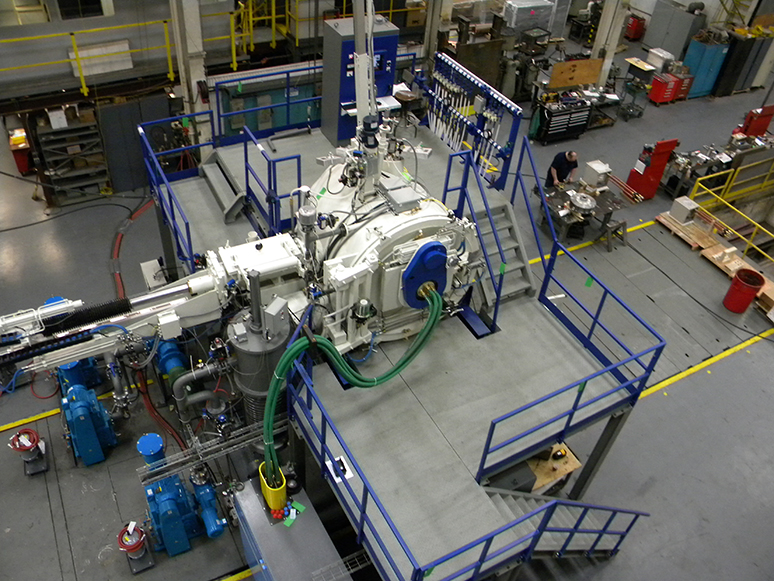

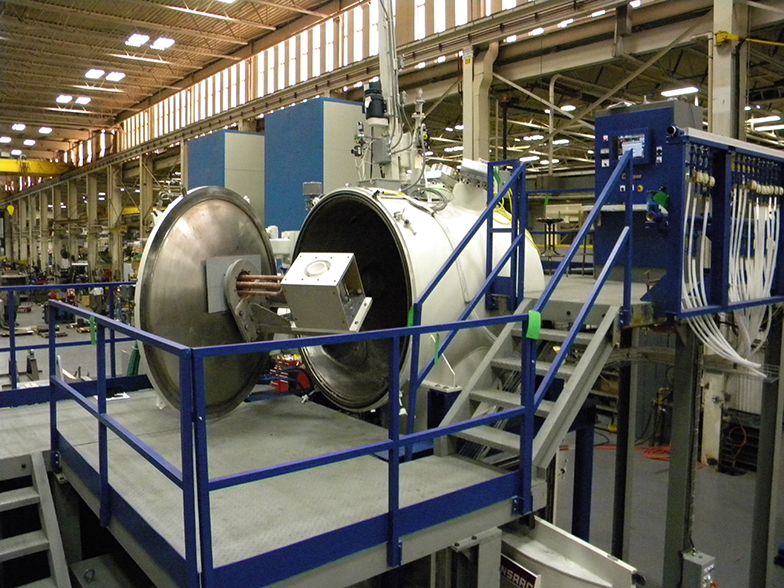

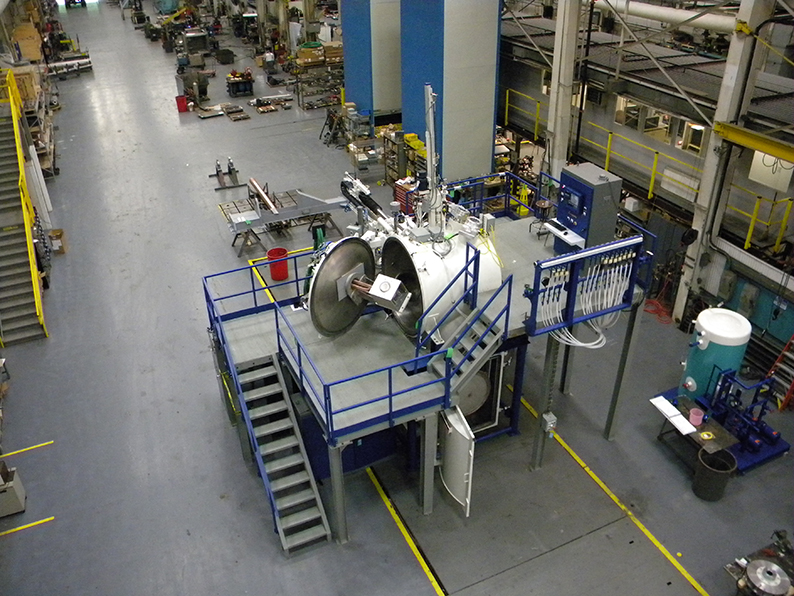

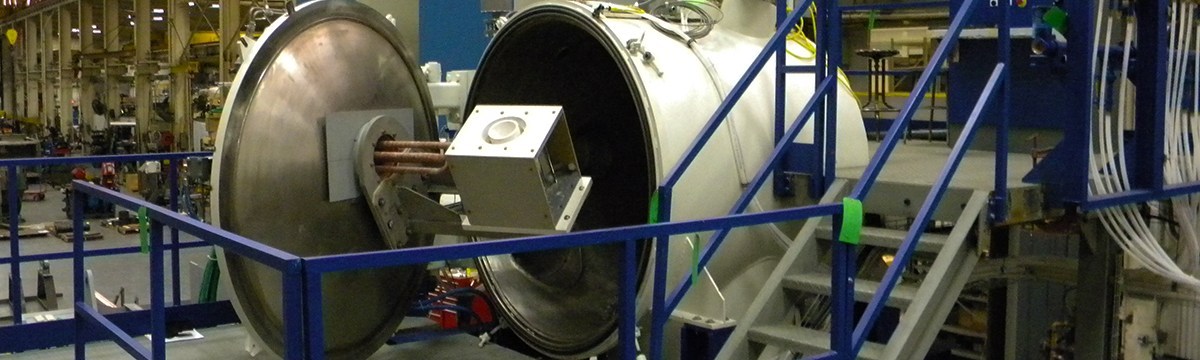

Vertical Vacuum Precision Investment Casting Furnaces

Consarc’s line of Vacuum Precision Investment Casting (VPIC) furnaces are uniquely designed to ensure the production of repeatable products with minimal maintenance and high furnace availability. Parts with an Equiax grain structure are easily produced in a VPIC and with the addition of a Mold Heater and Water Cooled Chill Plate, Directionally solidified and Single-Crystal castings are able to produced as well. Consarc offers many features to ensure the highest productivity including, automatic baffle exchange, liner and billet charging, and an independent liner dump chute. Whatever your process entails a Consarc VPIC can be tailor designed to suit your needs.

Features

• Vertical, or pitless vertical furnace configurations.

• Door mounted, rapid exchange melt coils, without any power or water connections internal to the vacuum chamber.

• Melt coil translation system for accurate pouring with Teach Pour

• Vertical billet charging with single use liner insertion and removal capability

• High speed mold transfer with multi position control

• Precision mold withdrawal system

• Large capacity vacuum systems for fast mold chamber evacuation

• Automatic temperature control of molten metal with optical pyrometer

• PLC based automated controls with full SCADA

• Stainless steel melt chambers for continuous high vacuum operation

• Robust delta seals on main chamber sealing flanges

• Water cooled articulating mold chamber isolation valve (Vertical Units Only)

• Custom engineered and designed equipment specifically for individual user’s process

Tech Specs

| Standard Products | PC-25 (Vertical) | PC-50 (Vertical) | PC-100 (Vertical) | PC-100 (Vertical) | PC-100 (Vertical) |

| Max Cast Weight | 25 kg | 50 kg | 100 kg | 150 kg | 200 kg |

| Max Mold Diameter | 550 mm | 700 mm | 800 mm | 950 mm | 1000 mm |

| Max Mold Diameter (DS) | 400 mm | 550 mm | 600 mm | 700 mm | 800 mm |

| Mold Height | 500 mm | 750 mm | 800 mm | 1000 mm | 1500 mm |

| Mold Height (DS) | 400 mm | 600 mm | 700 mm | 800 mm | 1000 mm |

| Isolation Valve Diameter | 600 mm | 750 mm | 900 mm | 1000 mm | 1050 mm |

| Melting Power Supply | 125 kW | 175 kW | 225 kW | 225 kW | 325 kW |

| Optional Mold Heating Power Supply |

125 kW | 175 kW | 175 kW | 225 kW | 225 kW |