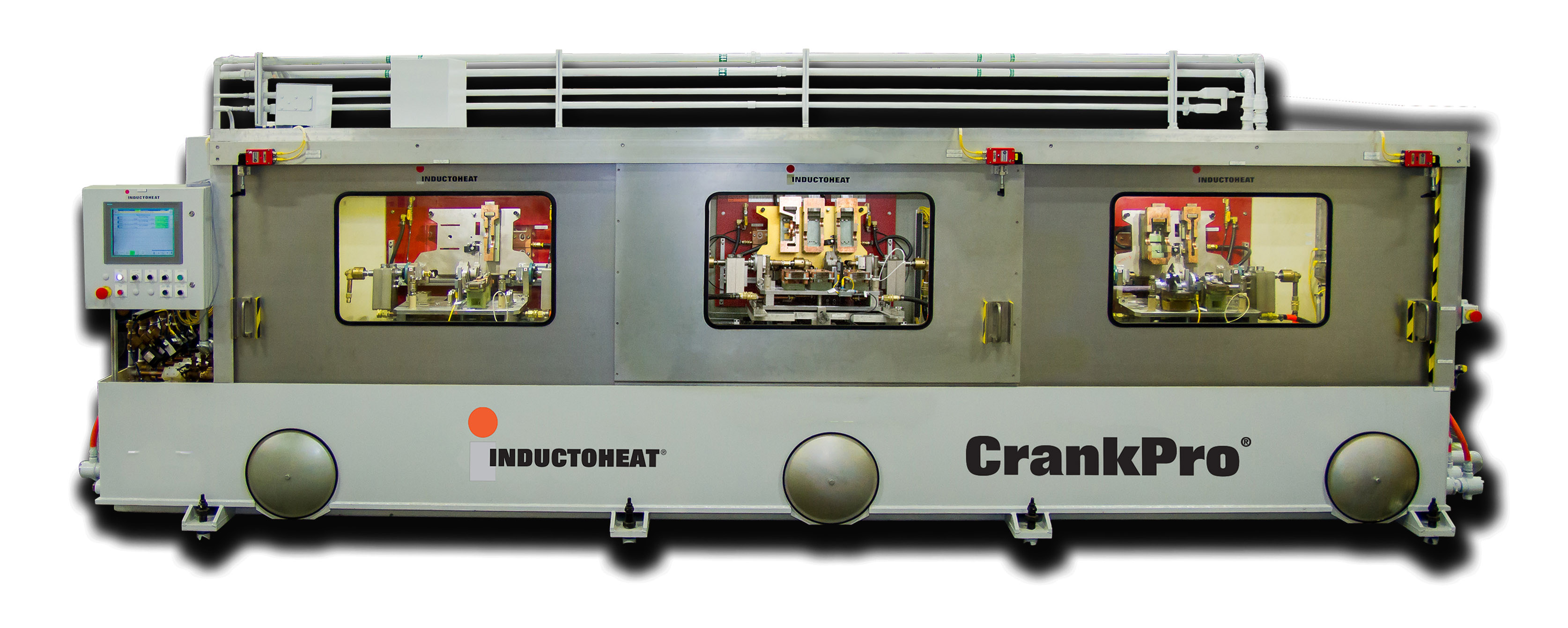

CrankPro™ Stationary Induction Heat Treating For Crankshafts

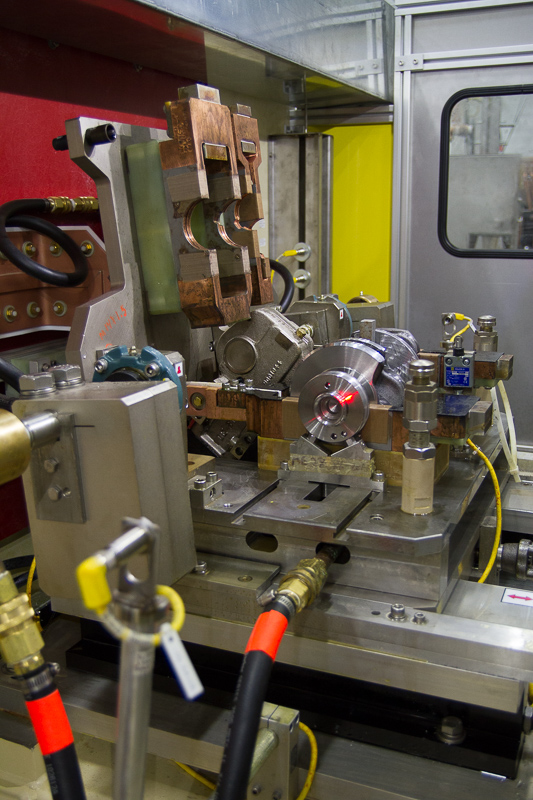

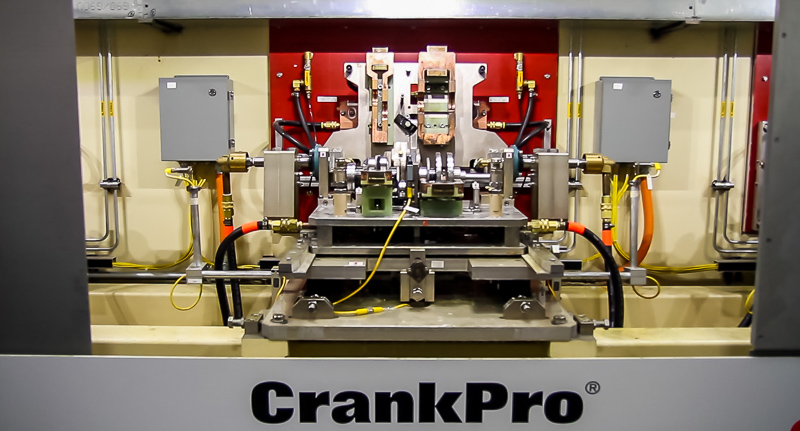

CrankPro™ Induction Heating Systems utilize patented SHarP-C™ (Stationary Hardening Process for Crankshafts) hardening technology, which eliminates work piece rotation during the induction heat treating process. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. There are several practical, economical and technical benefits associated with SHarP-C™ hardening technology including extended tooling life, dramatically reduced maintenance cost, simple operation, improved heat treating quality and dramatically reduced distortion.

Features

Increased Production

- Non-contact / Stationary Hardening Process

- Only 1 moving part per station (Open/Close)

- Increased throughput – Short heat times – less than 4 seconds

- Production rates up to 90 parts/ hour

Improved Quality

- Robust CNC machined inductors. No moving powered parts

- Distortion is typically less than 25 microns, subsequent operations may be improved

- Improved microstructure of hardened material

Reduced Downtime

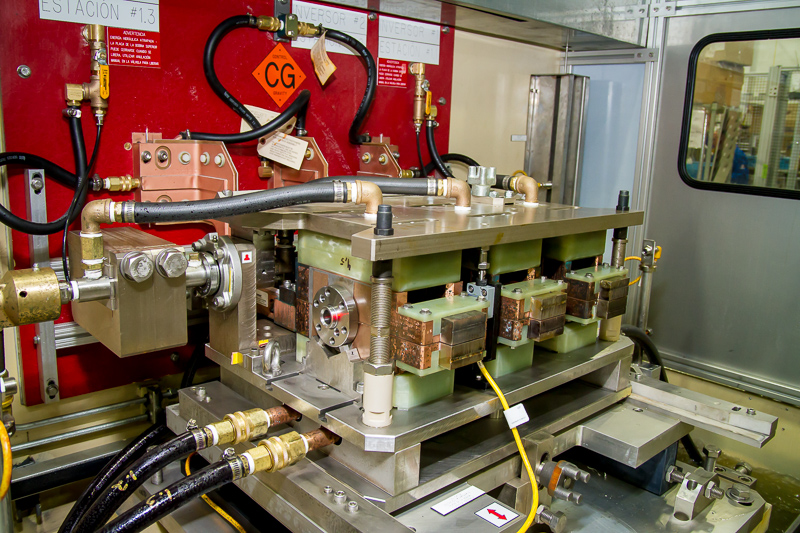

- Production ready “quick change” pallet assembly for fast coil changeover

- Improved tooling life

- Redundant duel bag quench filtration system, permits filter replacement while machine remains in operation

- Modular design permits fast part changeovers

Reduced Operating Costs

- Substantially reduced operating cost compared to rotational induction heat treating

- Substantially reduced maintenance cost

- 50% less energy consumption compared to rotational induction heat treating

Tech Specs

| Model | 2 Station | 3 Station |

| Machine Dimensions | 190” W (4826 mm) x 89” D (2264 mm) | 265″ W (6731 mm) x 89.64″ D (2277 mm) |

| Weight | 24,250 lbs. (11,000 kg) | 22,046 lbs. (10,000 kg) |

| Production Capacity | Up To 90 Parts Per Hour | Up To 60 Parts Per Hour |

| Power Output | 150 kW, 300 kW or 450 kW | |

| Output Frequency | 10 – 30 kHz | |

| Work Piece Type | Various Crankshafts ( V10, V8, V6, I4, I3) Pins, Mains, Oil Seals | |

| Coil Pallets | 2 SHarP-C™ Coil Pallets | 3 SHarP-C™ Coil Pallets |

| Controls | Standard Siemens PLC (Other control options available) | |

Accessories

- Overhead gantry or robotic material handling system

- Quick-change pallet cart

- Tooling storage system

- Process monitoring signature package

- Mist collection system

- Automatic quench concentration system

- Automatic deionized water filling

- Programmable machine start-up