Engineered Structural Sections

Overview

Engineered Structural Section (ESS) High Frequency (HF) beam welding is the process of forge welding three strips of steel to produce a sturdy and reliable structural section.

Thermatool’s research and development team pioneered scientific standards to improve the characteristics of HF welded structural beams. Thermatool’s Engineered Structural Sections are not forge rolled, they are HF forge welded. This innovative welding practice provides the most cost effective way to produce ESS.

Ultimate Process Control

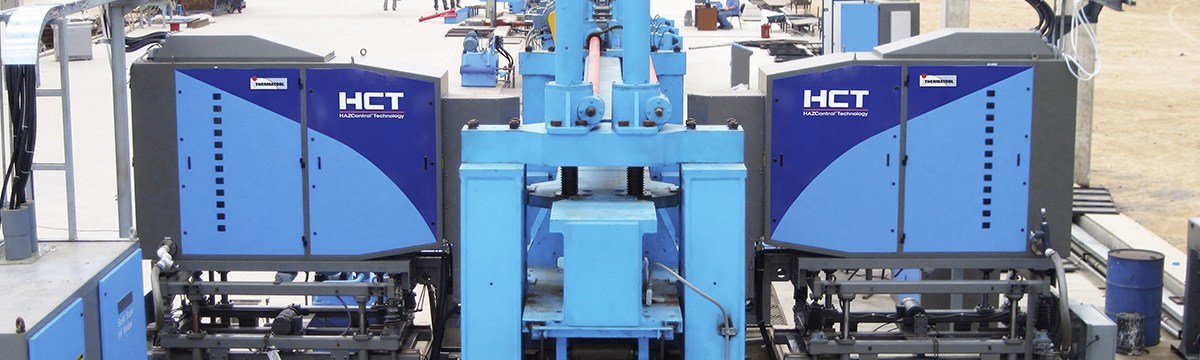

The forge weld, the strongest weld available, is accomplished through Thermatool’s HAZControl Technology™. The combination of selecting the right power and frequency gives Engineered Structural Section producers the ability to successfully weld different materials including aluminum, carbon steel, stainless steel, advanced high strength steel and even weathering steels.

High Frequency Contact Welding

The art of Solid State High Frequency contact technology to heat and subsequently forge weld Engineered Structural Sections at high speeds with maximum precision and strength, enables the production of virtually unlimited selection of custom beam profiles.

Features

Thermatool’s beam welding lines provide a benefit to design engineers and manufactures by allowing greater customization of beams. Offset beams in T and Z shapes are now easily produced to fit exact geometry load and length requirements. The beams can be manufactured with three dissimilar materials for the strongest, lightest most cost effective beam.

- Low capital investment when compared to hot rolled beam mills.

- Ability to deliver custom sections and meet shorter lead times.

- Make light weight and high performance sections.

- Cost of operation is low compared to hot rolled beams.

- Stainless Steel Engineered Structural Sections are now achievable with High Frequency Welding.

Tech Specs

Product size ranges:

50 mm – 100 mm web height

100 mm – 500 mm web height

Special applications with web height up to 700 mm available

Line layout includes:

- Coil infeed for three strips (two flanges, one web)

- Optional accumulators

- Strongback section for HF Weld process

- Two HF Contact Welders (top-flange and bottom-flange)

- Optional in-line post weld heat treat

- In-line Straightening Section

- Flying cutoff

- All material handling and controls