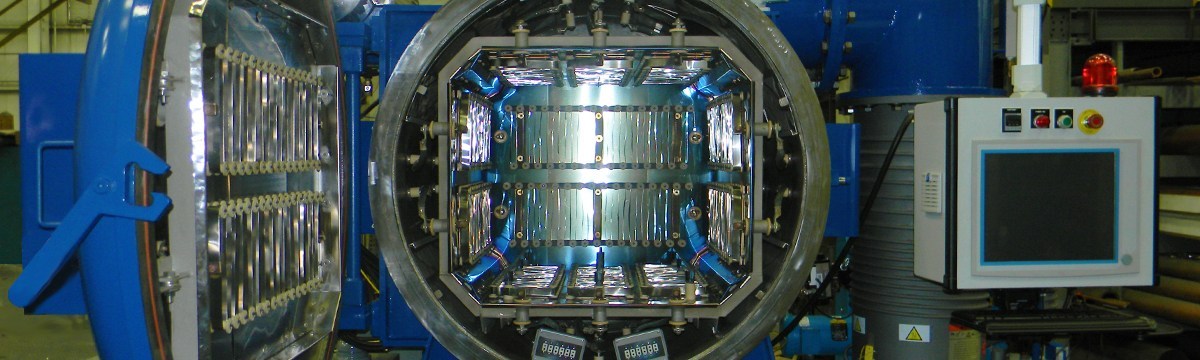

Vacuum Aluminum Brazing Furnaces

Vacuum Aluminum Brazing (VAB) is utilized to perform fluxless brazing of Aluminum components in a high vacuum environment. The process demands tight control of temperature uniformity together with low vacuum leak rates and high repeatability. VAB will provide a component with very clean, high quality, high strength brazed joints. Whilst offering a wide range of standard vacuum aluminum brazing furnace designs for a variety of applications, Consarc also has the flexibility to design for bespoke or individual customer requirements.

Features

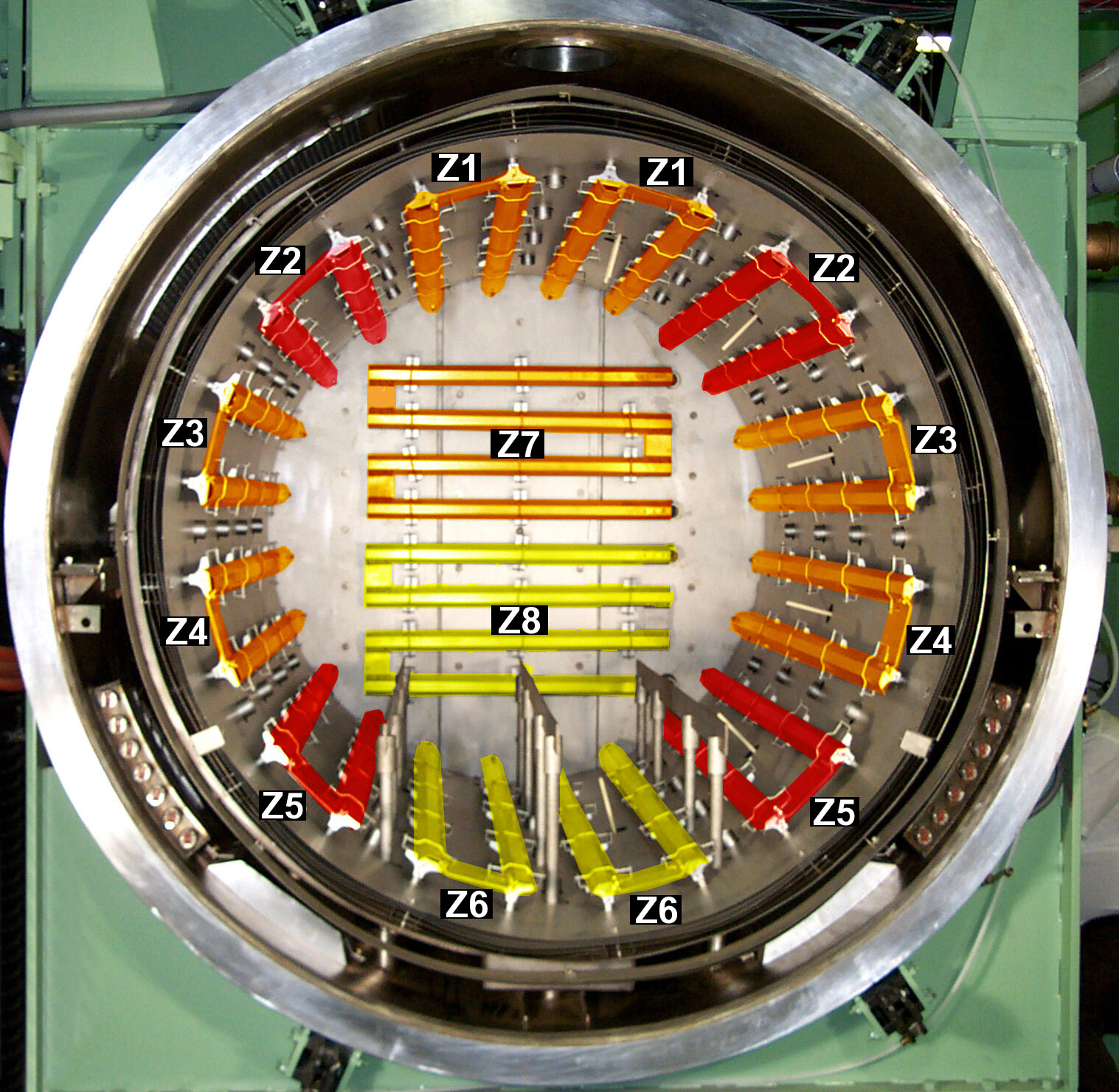

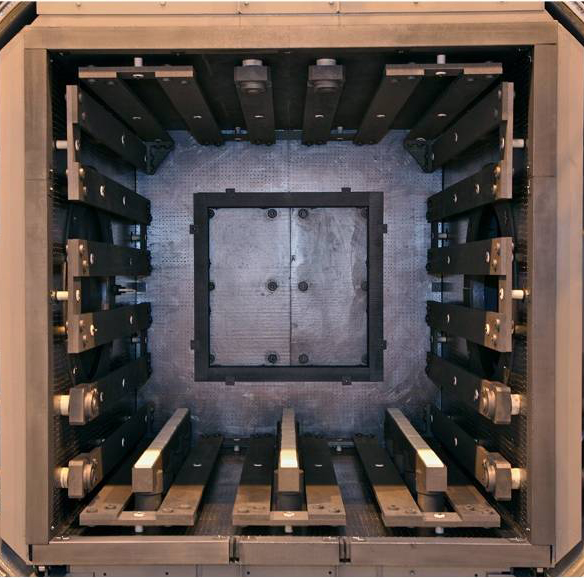

- Closely spaced ribbon heating elements with the edges facing the work provide the best in uniform heating characteristics.

- Temperature uniformity +/- 5oF

- Multiple ‘trimable’ heating panels for balance of heat input to match the workload and fixture thermal characteristics.

- Trimable heating panels up the height of the hot zone allows the heat input to be trimmed to match components /charge loads of varying height.

- Aluminum debris will pass through the edge facing bottom heating element panels – minimising potential for burn outs.

- The hot zone element panel modules can be easily removed to permit cleaning of the furnace. Individual panels can also be removed without the need for a full hot zone strip down.

- Element repairs made simple. Small sections of the strip elements can be repaired without the need for full replacement

- Hot zone shields are overlapped and spaced to permit easy escape of gases from the work assembly to provide optimum vacuum performance.

- The tank walls of the furnace are maintained in a hot condition to prevent condensation of atmospheric moisture when the chamber door is open.

- Insulated non-water cooled power feedthroughs prevent condensation of magnesium which reduces arcing potential.

- Internal inert gas cooling systems or external air blast cooling stations are available

- Fully integrated and automated loading systems.

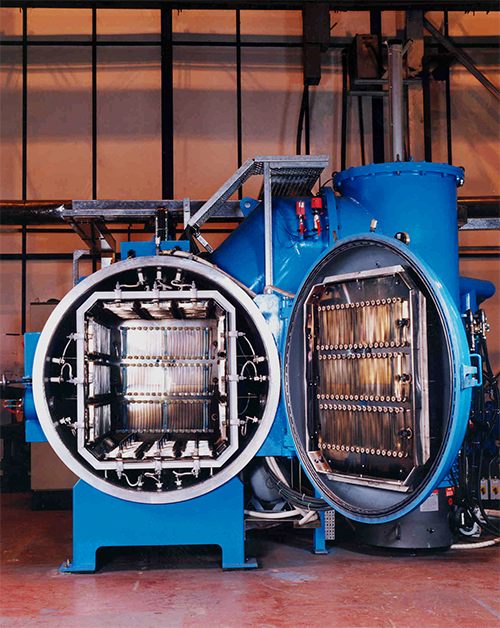

- Integration with a Vacuum Deoiing furnace to provide an “in line” process system for high productivity with minimum product handling.

- Extensive process experience.

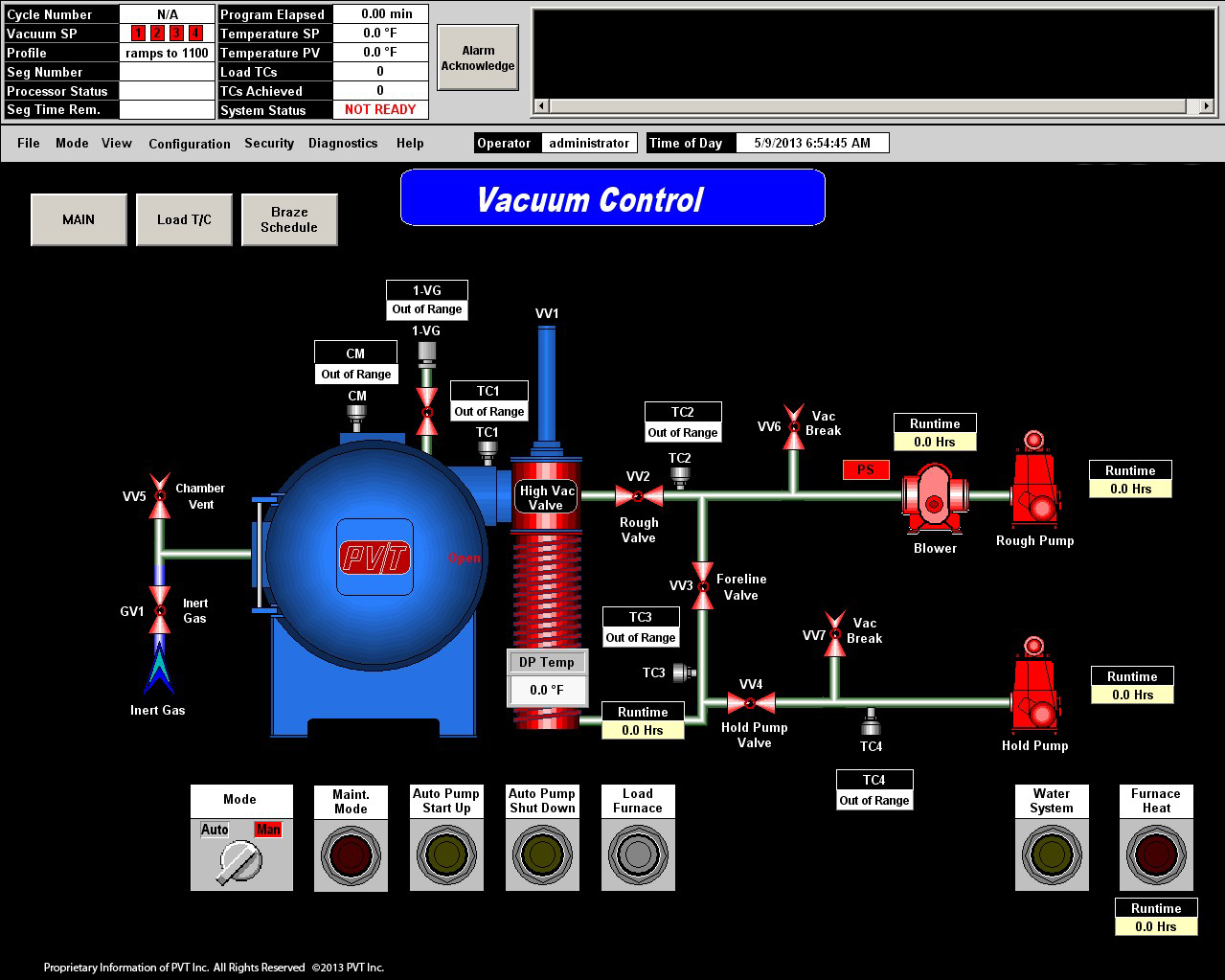

- PLC and PC SCADA providing completely automated control of the brazing furnace and data recording

- Compliant with NADCAP and AMS2750 requirements if required

- Complete furnace system including all interconnecting services, water lines, air lines, gas lines and electrical cables.

- Fully assembled and functionally tested prior to shipment

Tech Specs

Aerospace/Automotive (small volume)configuration

Model No Charge Size

| Height(mm) | Length(mm) | Width(mm) | |

| VAB 22-24-21 | 22”(550) | 24”(610) | 21”(535) |

| VAB 21-24-21 | 21”(535) | 24”(610) | 21”(535) |

| VAB 30-32-22 | 30”(760) | 32”(810) | 22”(550) |

| VAB 30-39-22 | 30”(760) | 39”(1000) | 22”(550) |

| VAB 30-48-22 | 30”(760) | 48”(1200) | 22”(550) |

| VAB 34-28-36 | 34”(865) | 28”(710) | 36”(915) |

| VAB 34-28-60 | 34”(865) | 28”(710) | 60”(1525) |

| VAB 36-28-48 | 36”(915) | 28”(710) | 48”(1200) |

| VAB 36-41-60 | 36”(915) | 41”(1045) | 60”(1525) |

| VAB 36-48-32 | 36”(915) | 48”(1200) | 32”(810) |

| VAB 36-71-32 | 36”(915) | 71”(1800) | 32”(810) |

| VAB 48-48-48 | 48”(1200) | 48”(1200) | 48”(1200) |

| VAB 48-48-120 | 48”(1200) | 48”(1200) | 120”(3050) |

| VAB 54-54-54 | 54”(1370) | 54”(1370) | 54”(1370) |

Automotive (medium – high volume) configuration

Model No Charge Size

| Height(mm | Length(mm) | Width(mm) | |

| VAB 62-96-16 | 62”(1580) | 96”(2450) | 16”(425) |

| VAB 62-136-16 | 62”(1580) | 136”(3450) | 16”(425) |

| VAB 65-96-16 | 65”(1640) | 96”(2450) | 16”(425) |

| VAB 65-104-16 | 65”(1640) | 104”(2650) | 16”(425) |

| VAB 65-136-16 | 65”(1640) | 136”(3450) | 16”(425) |

| VAB 72-72-16 | 72”(1830) | 72”(1830) | 16”(425) |

| VAB 72-96-16 | 72”(1830) | 96”(2450) | 16”(425) |

Cyrogenic – Large individual Product Size

Model No Charge Size

| Height(mm | Length(mm) | Width(mm) | |

| VAB 66-244-54 | 66”(1675) | 244”(6200) | 54”(1370) |

| VAB 72-275-59 | 72”(1830) | 275”(7000) | 59”(1500) |

| VAB 82-275-59 | 82”(2100) | 275”(7000) | 59”(1500) |

Accessories

- Dry Screw pumping systems

- Stainless steel inner chamber walls

- Cryogenic panels and pumping systems

- Outer Loop Cooling System (Open or Closed)

- Installation Services

- Magnesium traps and condenser panels

- Load tray and carriers

- Manual and automated load handling systems

- Process heating cycle optimisation features

- Internal forced gas cooling systems

- External air blast cooling systems