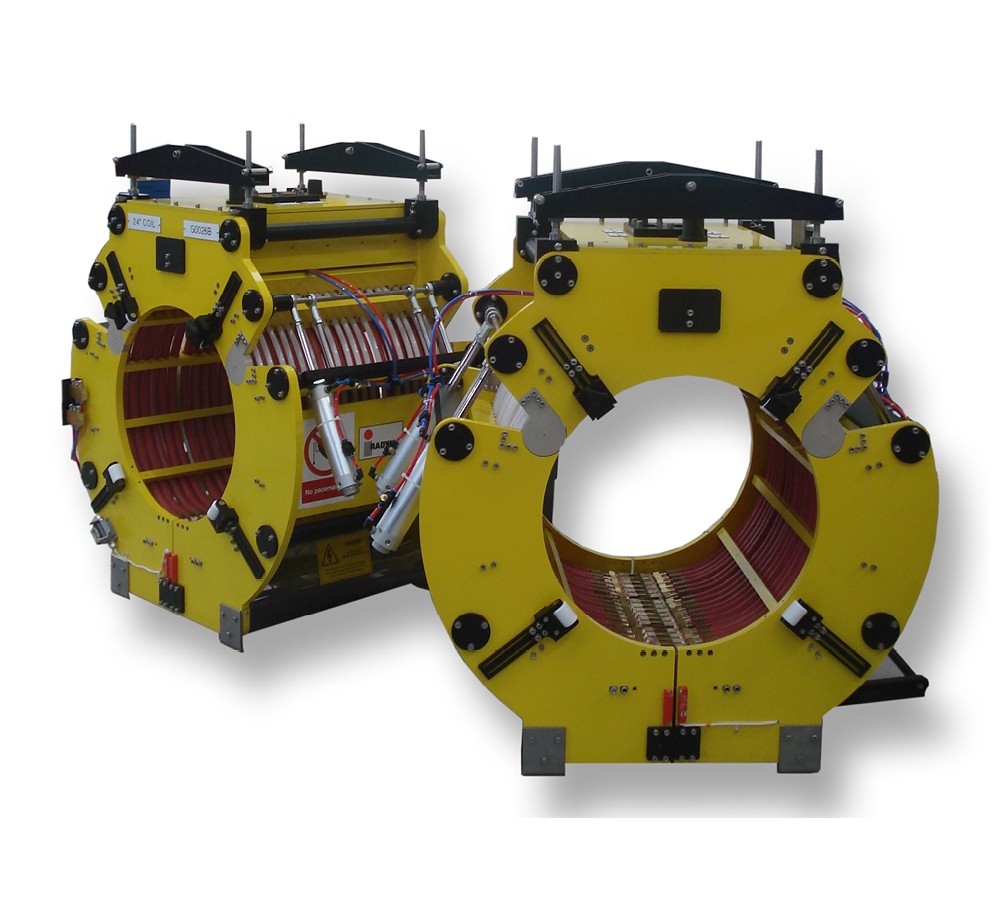

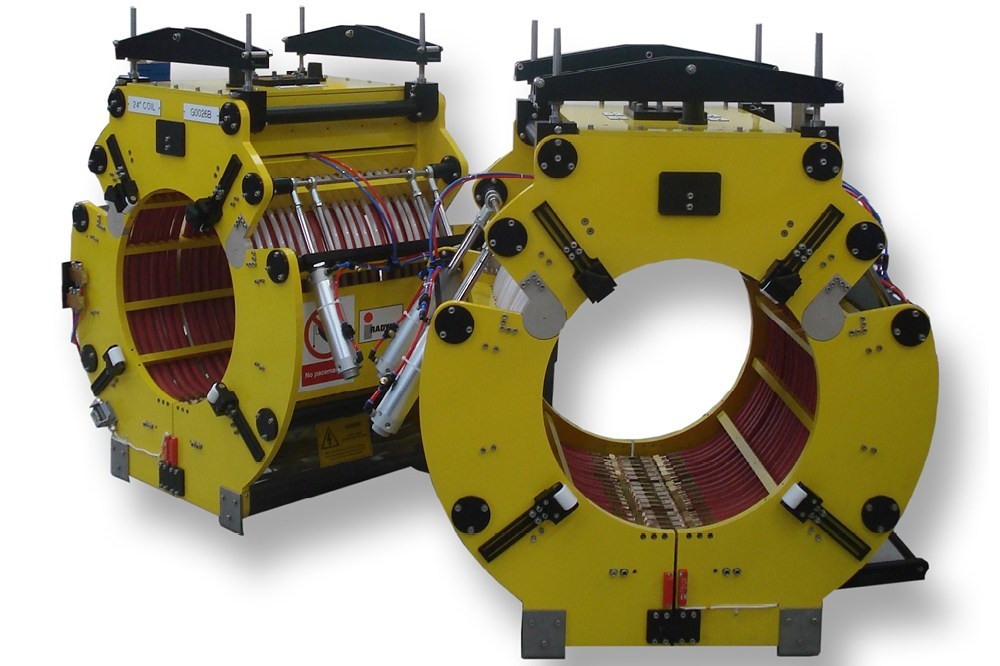

Offshore Clam Coils

Radyne Offshore Clam Coil systems are designed for use in offshore pipe laying applications and utilized for a number of pipe heat treatment tasks.

The coil is manufactured in a non-conductive composite frame to support the water-cooled coil wraps – with an over center clamp to manually clamp the clam-type coil around the joint area. For larger pipe diameters, it supports pneumatic automated operation.

Features

Pre & Post Weld Heat Treatment

The coil is designed to heat the butt joint to the appropriate temperature over a narrow band during operation – reducing the HAZ (Heat Affected Zone) to a minimum.

Fundamental to the process of butt welding, to ensure the integrity of the welded joint, the Radyne induction heat process provides the perfect method of heating pipes to the correct temperature within closed limits.

For post weld heat treatment, PLC controlled heat programs power clam coils, as dictated by the steel grade of the pipe.

Shrink Sleeve Application

Radyne Offshore Clam Coil Systems are also used to apply heat during the application of shrink sleeves which surround the pipe joints.

The induction-powered Clam Coil System allows for a quicker, safer shrink-sleeve application without the use of gas fired torches.

Additional Applications

- Pre Heat Prior to Welding,

- Pre Heat for Shrink Sleeve Application,

- Post Weld Heat Treatment