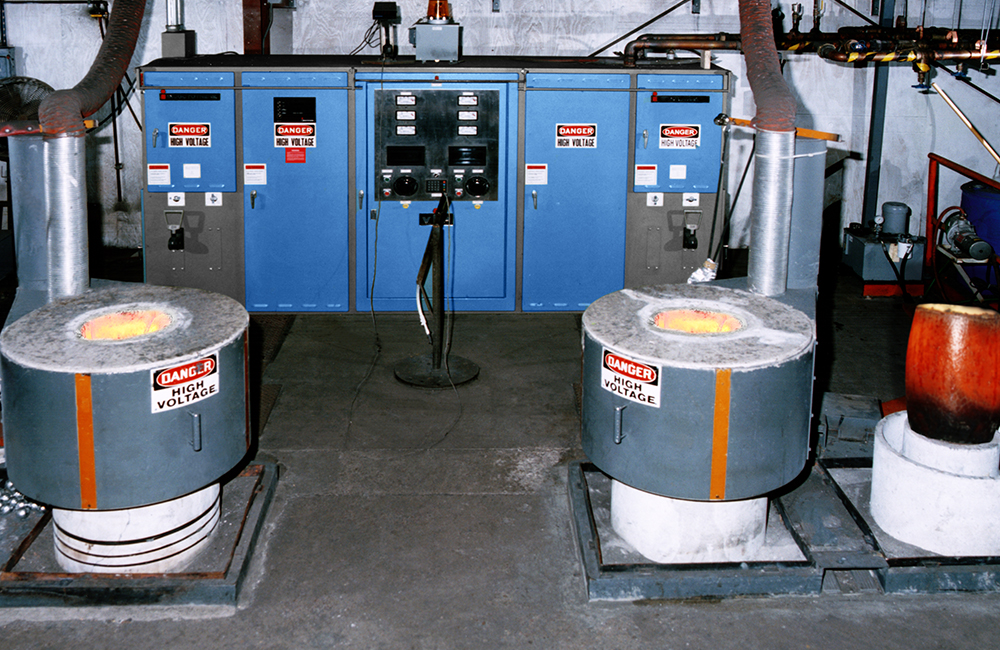

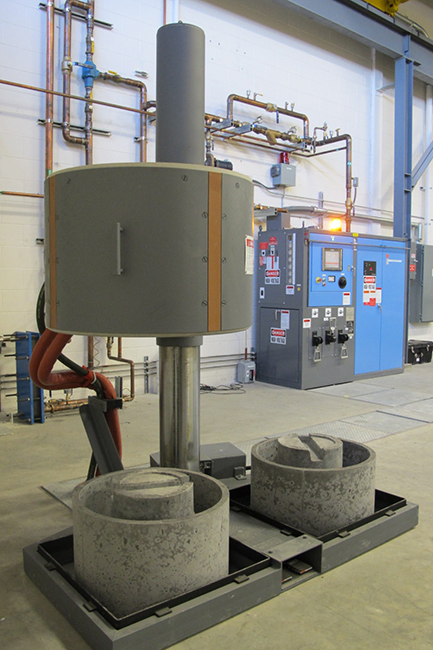

Lift-Swing Furnaces

Inductotherm Lift-Swing Furnaces are free-standing units that install right on the foundry floor. They are an excellent alternative to our Push-Out Furnaces when sub-surface conditions or foundation restrictions make it impractical to provide a pit that is required for the Push-Out Furnace’s cylinders.

Features

Lift-Swing Furnaces offer nonferrous and precious metal casters an easily installed, highly productive crucible melting system. When the charge in the first crucible is melted and ready to be poured, the induction coil assembly is raised, swung to the second crucible and lowered to start the new melt as the first crucible is removed for pouring. For easy, accurate transfer, machined slots guide coil assembly movement to the exact position. A rugged aluminum shell protects the coil while a specially designed base contains spills. Coil movement is controlled by a foot valve operating a cylinder within the support post. Either plant air or hydraulic operation is available.

Tech Specs

| Capacities | 50 to 300 Kilograms [120 to 675 Pounds] for Copper Alloys |

| 20 to 100 Kilograms [40 to 225 Pounds] for Aluminum Alloys | |

| Contact Inductotherm for Custom Solutions | |

| Standard Features | Electrical Interlock with Power Supply Unit |

| Machined Guide Slots for Precise Positioning | |

| Rugged Aluminum Shell | |

| No Pit Needed; Installs Directly on Foundry Floor | |

| Foot Valve Operated Cylinder | |

| Plant Air Coil Movement | |

| Optional Features | Fume Extraction Control Systems |

| Hydraulic Operation Coil Movement | |

| Pouring Cradle Systems | |

| Factory Tested | Critical Components |