Induction Vacuum Heat Treatment Furnaces

As an alternative to resistance heating Consarc offers a wide range of high temperature Induction heated vacuum furnaces. Induction heating is a very robust configuration and is normally preferred for the highest temperature applications up to 2500C or in certain arduous process environments e.g CVD / CVI. Consarc offers offer top or bottom loading induction heating furnaces

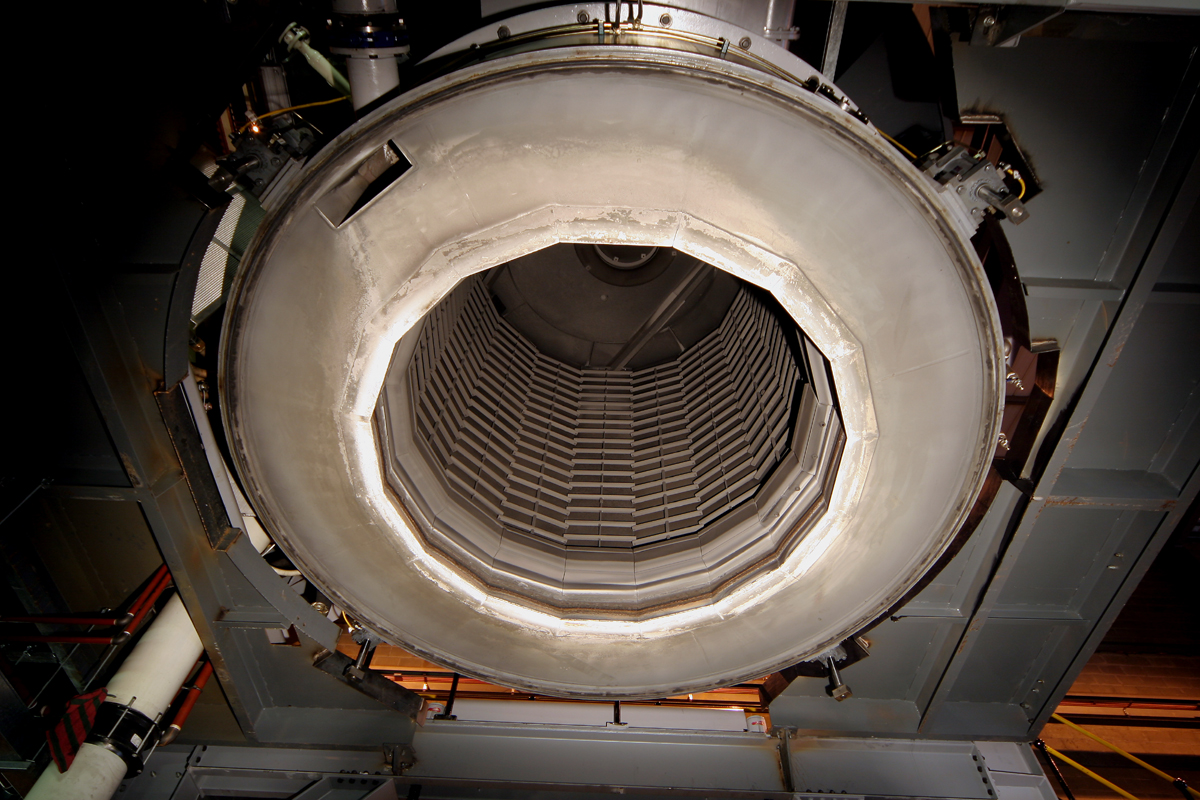

Vacuum induction heating furnaces utilise a static cylindrical induction coil with graphite susceptor and carbon based insulation.

Features

- Vacuum induction heating furnaces utilise a static cylindrical induction coil with graphite susceptor and carbon based insulation. Insulation pack and susceptor are designed to suit process type and customer preference.

- Solid susceptor can be provided to act as process gas retort / containment inside the hot zone or Consarc “mini-sceptor” for rapid cool down.

- Very robust at high temperature. No internal heater connections, insulators or joints and therefore not affected by thermal cycling or deposits / condensate from process,

- Single or multi zone (multi switch) Inductotherm induction power supplies and coils

- Heater control typically by auto retracting thermocouple up to 1400c and / optical pyrometer to 2500C

- Medium vacuum pumping systems with pipeline traps / filters to suit the process and application

- Forced gas cooling systems to reduce cycle time and improve productivity.

- Manual or automated gas flow control systems can be provided to suit the process and application.

- Fully integrated loading systems are provided with bottom loading furnace systems

- The experience and installations of Consarc are extensive. Consarc Group has supplied numerous furnaces including bespoke systems for unique applications.

- Consarc provide state of the art controls with PLC and PC SCADA providing completely automated control of the induction heating furnace. All data is stored and trended on the PC for analysis and quality control. Internet link via furnace PC to Consarc allows on line support for software updates and on line support

- Consarc supplies complete furnace system including all interconnecting services, water lines, air lines, gas lines and electrical cables.

- Consarc induction heating furnace systems are assembled and functionally tested prior to shipment ensuring a quick and trouble free installation on site.

Tech Specs

Model No Charge Size

| Dia (mm) | Height (mm) | |

| FVB 86-122-150

|

122″(1220)

|

150″(1500)

|

| FVB 96-150-150

|

150″(1500)

|

150″(1500)

|

| FVB 96-150-180

|

150″(1500)

|

180″(1800)

|

| FVB 96-180-180

|

180″(1800)

|

180″(1800)

|

| FVB 106-200-200

|

200″(2000)

|

200″(2000) |

| FVB 106-250-150 | 250″(2500) | 150″(1500) |

Accessories

- Dry Screw pumping systems

- Pipeline filters / traps

- Stainless steel inner chamber walls

- Outer Loop Cooling System (Open or Closed)

- Installation Services

- Manual and automated load handling systems

- Process heating cycle optimisation features

- Internal forced gas cooling systems