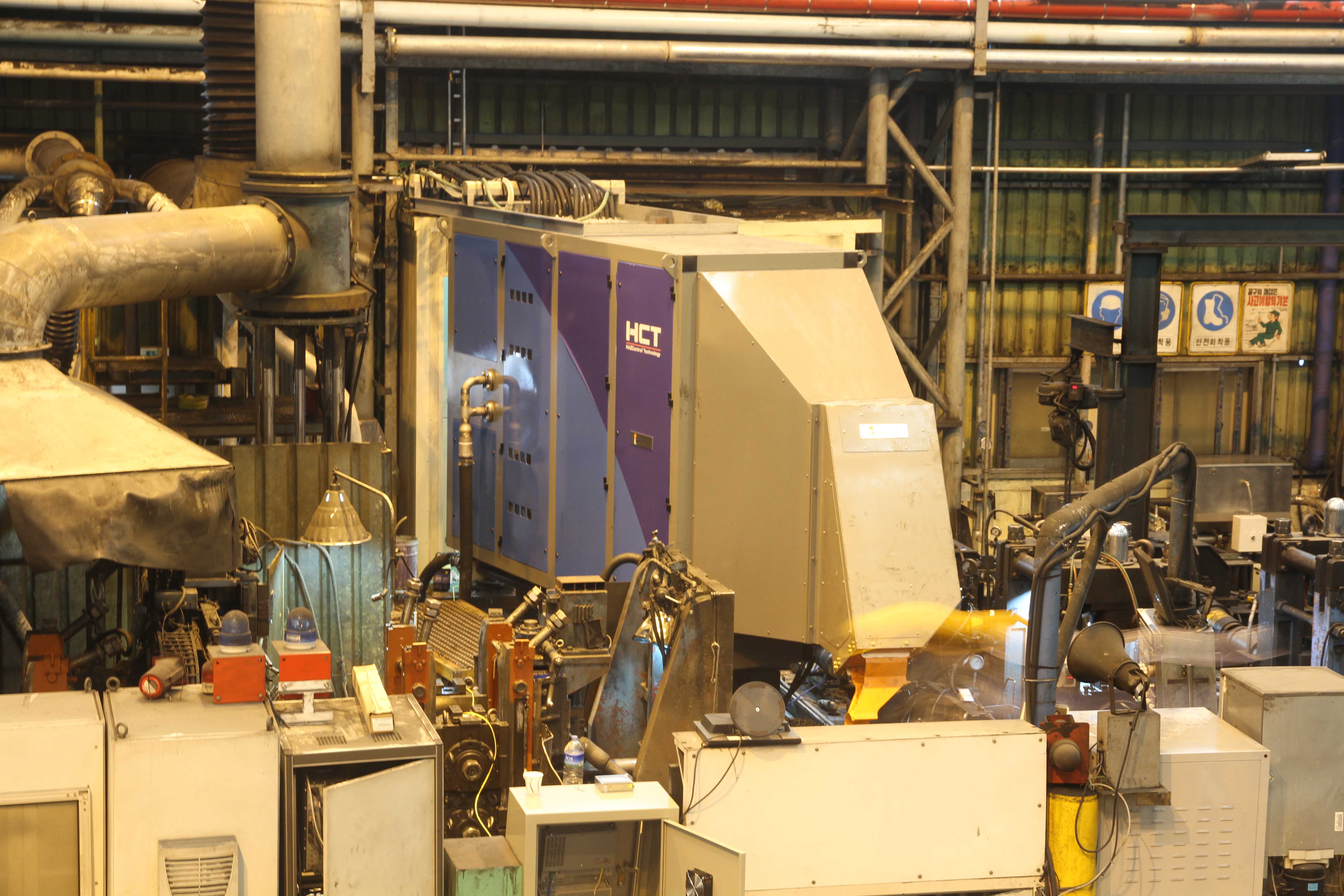

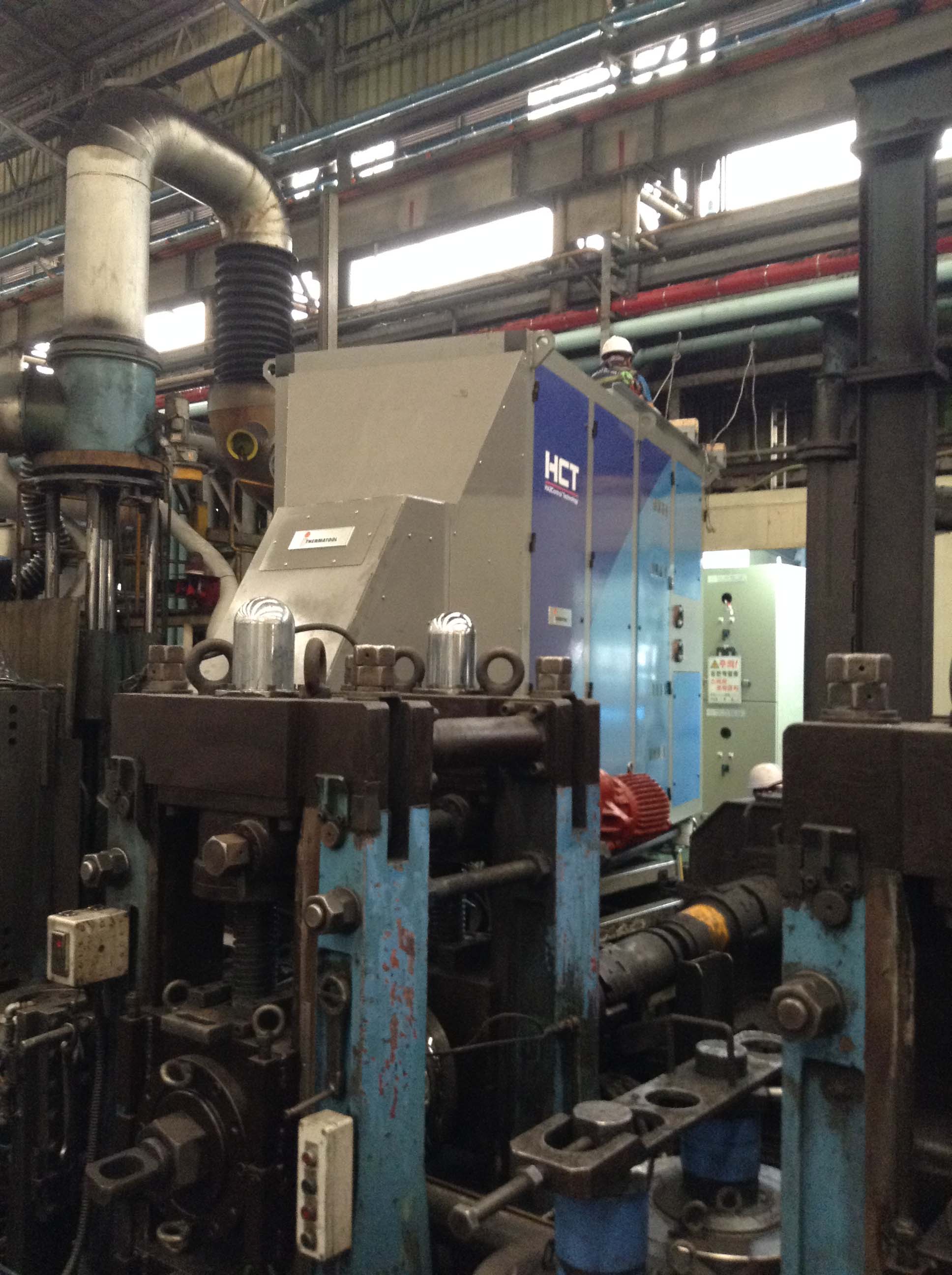

High Power HF Welders

With power ranging from 1200 – 1800 kW, Thermatool™ High Power HF Welders are capable of welding from 200 – 400 kHz with fixed or variable frequency. perform in the most demanding applications. Thermatool™ High Power HF Welders are available with the innovative 221 coil or the patented QuadContact™ weld tooling for the highest quality HF Weld available on the market.

Thermatool™ welders of over 1200 kW are installed in applications up to 610 mm (24 inch) diameter and up to 25 mm wall (1 inch) at speeds up to 40 mpm (130 fpm)

Features

- Up to 400 kHz HF Welding Frequency above 1200 kW

- Available with HAZControl™ Welder Technology variable frequency option

- Power set-point maintained within 0.5%

- Frequency set-point maintained within 1.0%

- Excellent low weld power output stability and regulation for welding at mill jog speeds (as low as 1% power)

- Power factor over 0.95

- High efficiency rating of 85%

- Available with dual induction/contact output

- DC Ripple less than 0.5%

- Low harmonic distortion rectifier

- Patented full range Thermatool™ AutoMatch™ software ensures full power output over wide range of product sizes

- Standard speed/power control simplifies operation and significantly reduces scrap through accurate control of weld power in relation to mill speed at start-up and ramp down

Tech Specs

Thermatool™ High Power Welder: 1200-1800 kW

Fixed Frequency Ratings: 200 kHz – 400 kHz

HAZControl™ Welder Technology Variable Frequency Bands Available: 250 kHz – 300 kHz, 300 kHz – 350 kHz, 350 kHz to 400 kHz

380, 480, 575 V at 50/60 Hz input compatible

Primary isolated power supply DC rectifier

No High Frequency output transformer

100 kW HF Module using MOSFETs

Accessories

ThermaView™

The ThermaView™ diagnostics package is a microprocessor based graphical software that gives mill operators and maintenance technicians a constant display of weld parameters in addition to easy-to-use trouble shooting indicators. A powerful preventative maintenance tool, ThermaView™ diagnostics package provides indication of welder status and operation.

Tooling

Genuine Thermatool™ tooling including induction coils and impeders ensure full weld power output and reliable operation. Thermatool™ induction coils are designed per application for long-life and optimized matching between the welder and the range of loads presented by different diameter and wall thickness combinations produced on a mill. Impeders and impeder booster pumps are available to minimize power used during welding and increase the efficiency of the welding process by ensuring that power is directed down the vee.