Fluid and Fuel Tube Brazing Systems

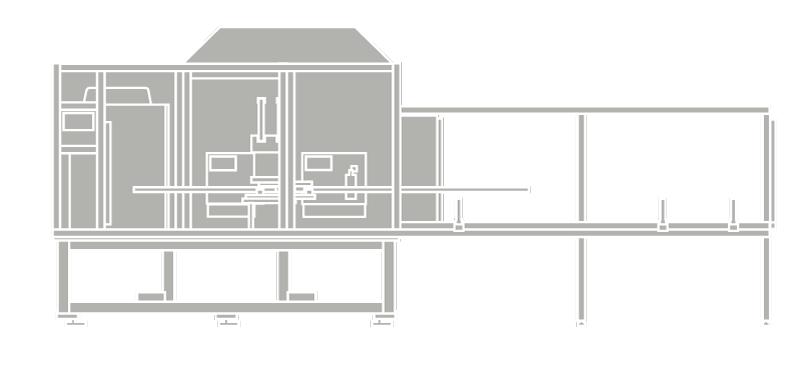

Radyne Brazing Systems deliver unmatched quality, repeatability, throughput, and safety that can’t be achieved with flame or hand induction systems. Radyne Brazing Systems feature low cost and quick change-over tooling to rapidly switch production to different parts. Features like these make Radyne brazing systems the ideal flexible solution for any brazing operation.

Features

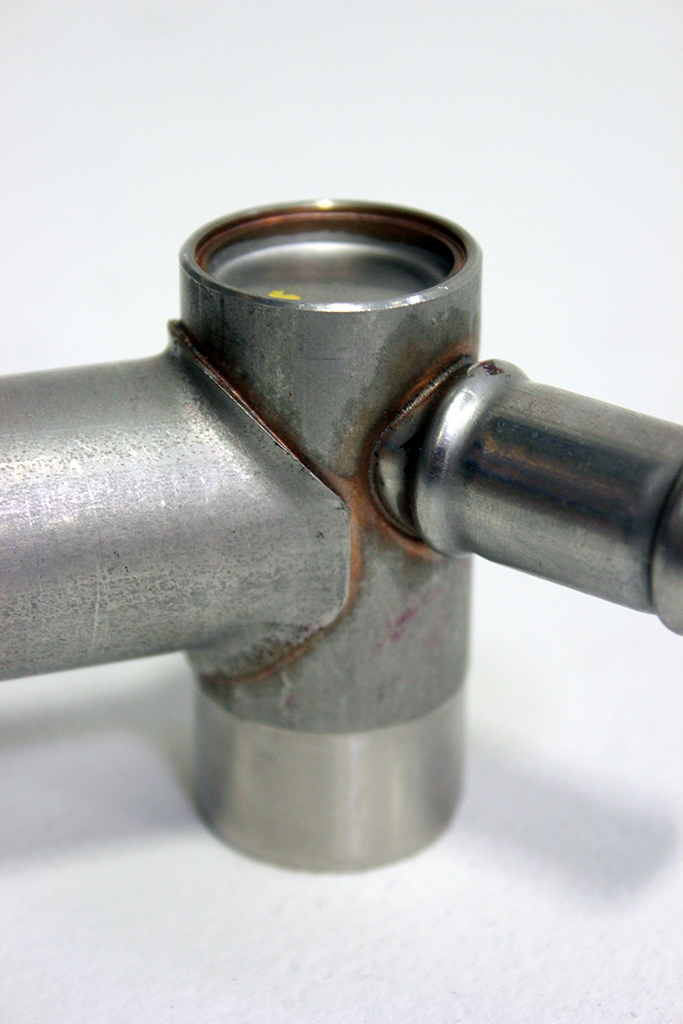

Stainless Steel Brazing, the newest line of stainless brazing systems offer repeatable controlled atmosphere brazing for many fuel, liquid, and gas fluid routing solutions. This stainless steel brazing system features new, innovative non-toxic brazing techniques that deliver solid, low cost braze joints.

- Fully automatic, semi-automatic part loading options

- Single or multiple assemblies per heat cycle

- Low or high power units to handle multi-position configurations

- Full PLC control and work cell management

- Integrated controlled atmosphere

- Suitable for fuel line tubes-to-brackets and tubes-to-fittings applications

Tech Specs

| Single Position | Dual Position | Quad Position | |

| Atmosphere | Nitrogen or Argon | Nitrogen or Argon | Nitrogen or Argon |

| Power Supply Configuration | Single – Direct Bus Single – Heat Station |

Dual – Direct Bus Single – Split Heat Stations |

Quad – Direct Bus Dual – Split Heat Stations |

| Part Rate | 1 Part Per Heat Cycle | 2 Parts Per Heat Cycle or 1 Part Per Alternating Cycles |

4 Parts Per Heat Cycle or 2 Parts Per Alternating Cycles |

Accessories

Dual Color Pyrometer 300-1000c Laser Sight

Single Color Pyrometer Infrared 1500-2500