Field Joint Heating & Coating

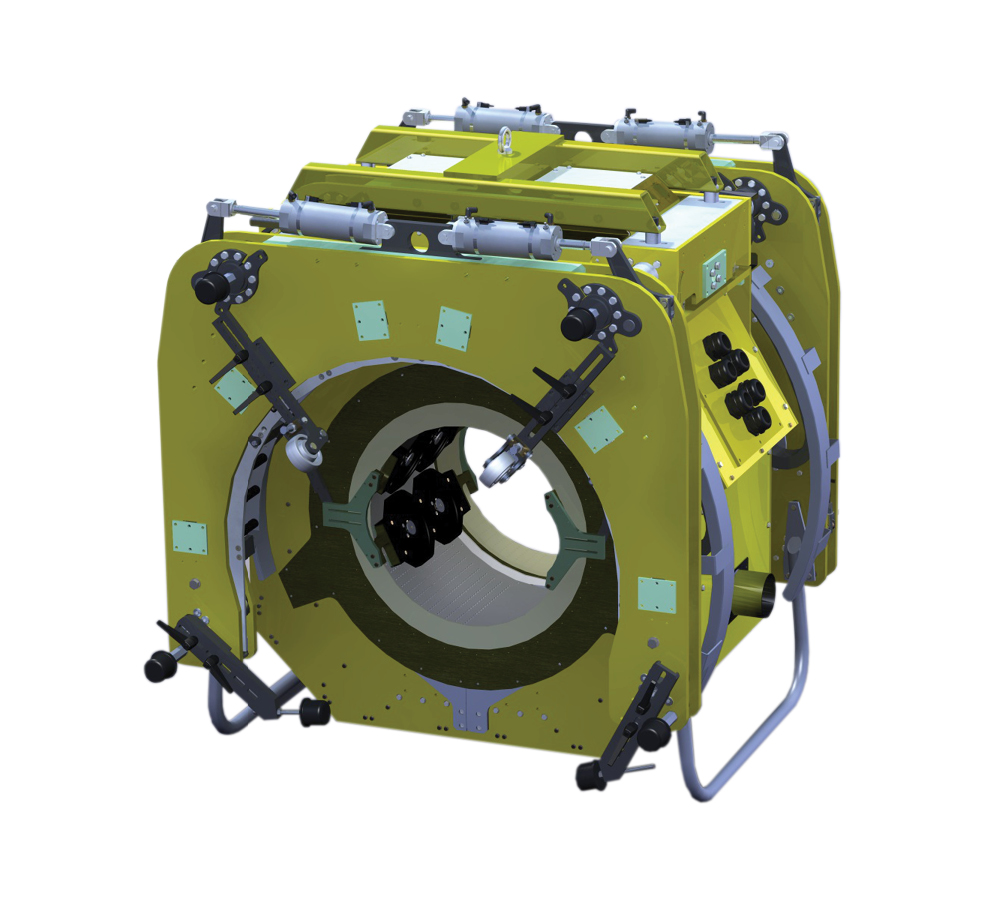

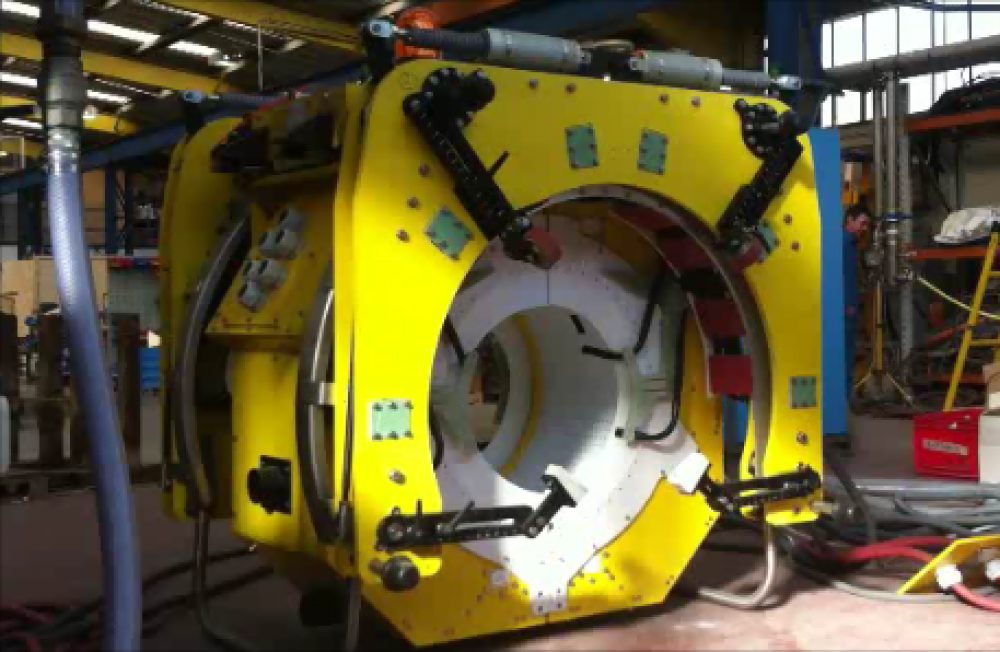

Radyne Merlin™ Systems deliver the most efficient means of heating and coating field joints by carrying out both operations simultaneously.

This is a major benefit to offshore pipe laying organisations as the Merlin™ System provides a reduced field joint processing cycle time, allowing a faster throughput of pipe preparation prior to laying.

Low temperature pyrometers and associated electronics are also included. The pyrometers will measure surface temperature of the steel pipe prior to the application of the FBE coating. Once the surface has reached a pre-determined temperature, the pyrometer will trigger the FBE coating process.

Merlin™ Coating applies a precise two-coat FBE and copolymer coating, delivering vastly improved cycle times and quality, vertical or horizontal application, and minimum manning levels. The benefits of the Merlin system have been proven on several international pipeline projects.

Features

- Integrated induction coils in an easy automated open/close system

- Fully automated precision control and application of a two-coat FBE and co-polymer coating

- Multiple coating heads providing a faster, more even coating

- Vertical and Horizontal operational capability

- Standard modular frames and assemblies allow for simple infield reconfiguration for multiple applications

Tech Specs

| Pipe Size range | 8-48 in [203-1219 mm] |

| Nominal Coil Size | 10-48 in [254-1219 mm] |

| FBE Thickness | 13.37 mil [350 μm] |

| Total Layers | 7-10 |

| Min Completion time | 55.1-137.2 s |