Electrode VIM Furnaces

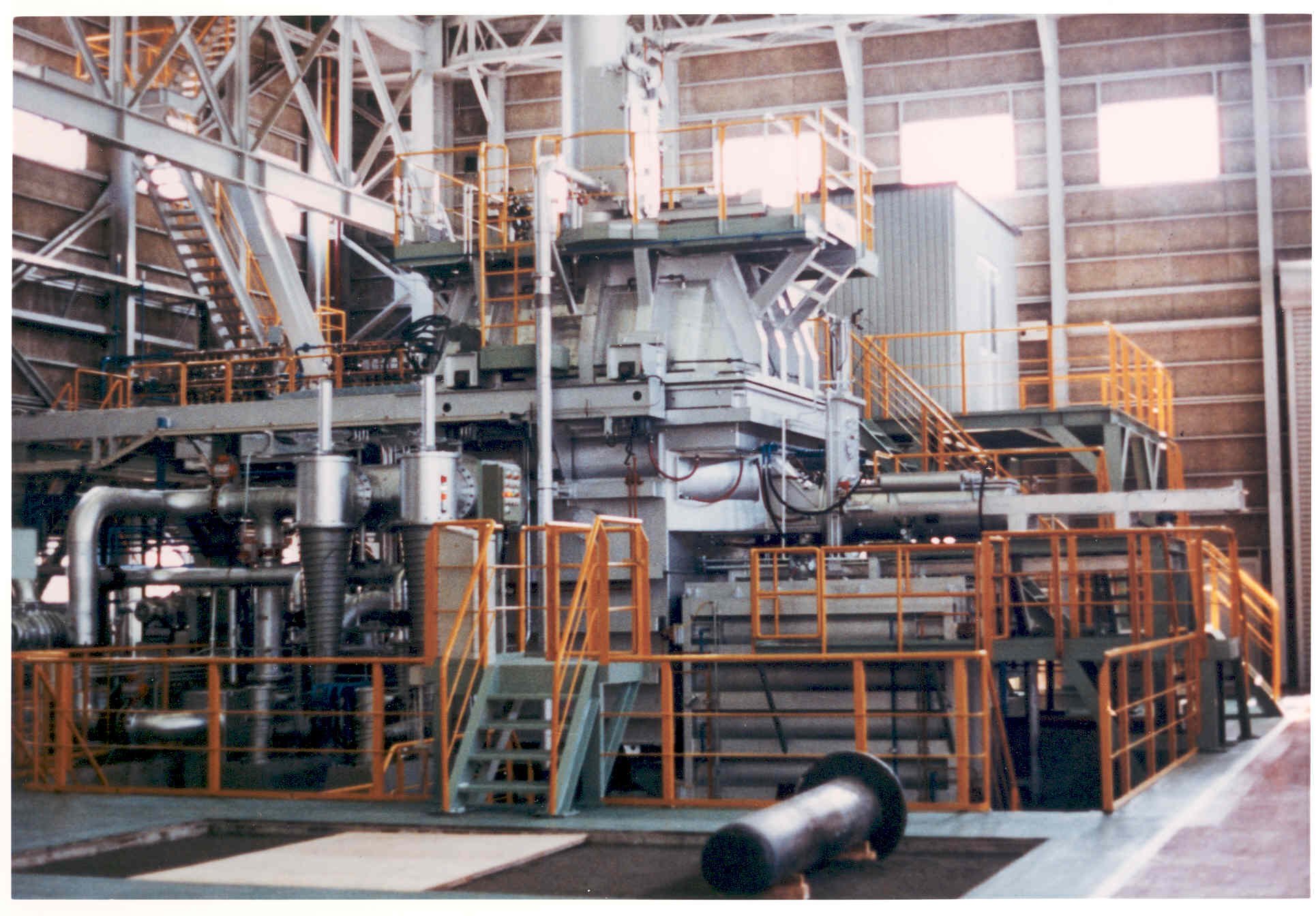

Electrode VIM systems are the largest VIM systems with heat sizes ranging from 5 tons to 30 tons. Electrode VIMs typically pour several electrode mold setups which could be as much as 5 meters (16.4 feet) in length.

Features

- Rugged steel shell induction furnace

- Rapid exchange features to minimize furnace down time

- Efficient Inductotherm power supplies and auxiliary stirring

- Multiple chamber systems with mold chambers, charging chambers, and hot tundish insertion systems

- Multiple charging systems for rapid feeding of a wide variety of charge materials

- Multiple mold pouring via mold cars or turntables; top pouring or bottom pouring (‘uphill casting’) can be utilized

- Low conductance loss ‘wet’ filters to protect vacuum pumps and minimize fire hazards

- Computer and PLC based controls with full SCADA

- Remote operation via CCTV

Tech Specs

Multiple Charging Systems:

- Large capacity overmelt chargers for primary bucket charging of high density charge materials. Charge weights to 5t are possible depending on the furnace refractory dimensions. Large capacity chargers incorporate dual hoists to allow controlled opening of charge buckets.

- Secondary overmelt devices for temperature probe insertion, sample taking, and late alloy additions

- Overmelt chargers utilize a custom-designed water-cooled overmelt isolation valve to over 1.3 m in diameter incorporating vacuum seal protection when open for increased reliability

- Vibratory side feeders for primary charging of low density charge materials

- Other charging systems for low headroom installations are available

Vacuum System:

- Three stage vacuum pumping system incorporating oil sealed rotary pumps or dry type screw pumps, roots type mechanical blowers, and oil vapor booster pumps for finalizing vacuum levels in the 10-3 Torr range

- Oil wetted vacuum filters for control of pyrophoric additions such as NiMg

- Large electrode VIM systems may incorporate steam ejector or steam hybrid vacuum pumping systems

- State-of-the-art safety systems incorporating overpressure relief valves and argon purging

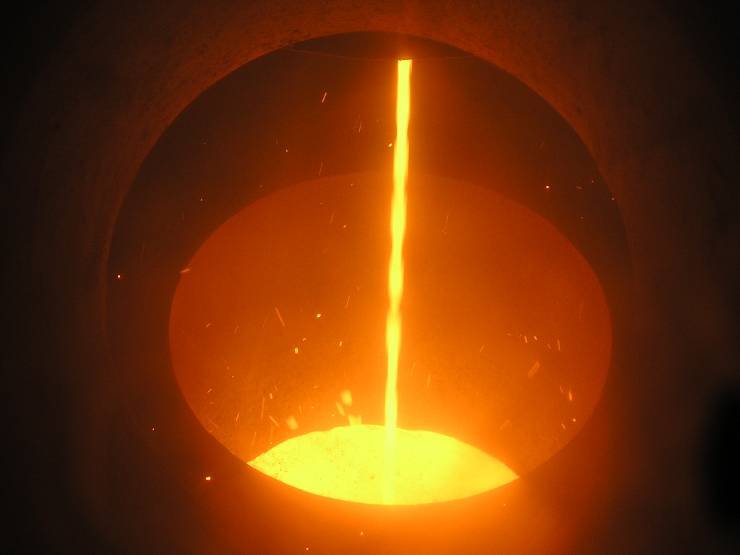

Mold Pouring:

- Hot tundish insertion chargers configured to insert an externally preheated refractory tundish into the pour position within a few minutes

- Deep tundishes on large furnaces can contain stopper rod assemblies

- Programmable control of mold car / turntable movement

Controls:

- Computerized control and SCADA systems

- TV cameras on remotely actuated site ports for remote operation

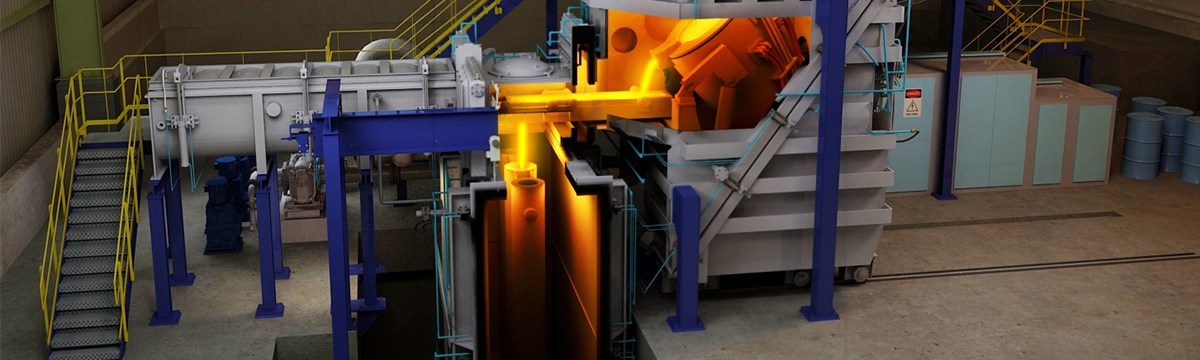

Furnace Layout

Two furnace layouts are typically utilized: Rollaway Head and Door Mounted Furnace.

Rollaway Head furnaces have the following features:

- Good access to the furnace top and spout

- Simple power supply bus arrangement

- Good ability to inspect the lining and furnace coil

- Able to frit lining or perform wash heat in open air

Door Mounted Furnaces have the following features:

- Very easy access to melt chamber for cleaning

- More complicated power supply bus required

- Easy access to all of coil

- Less platforming required since there is no head movement