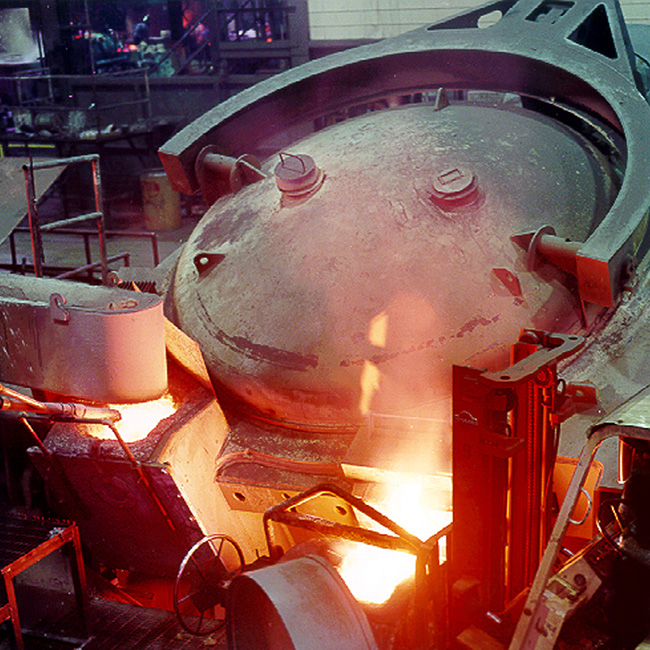

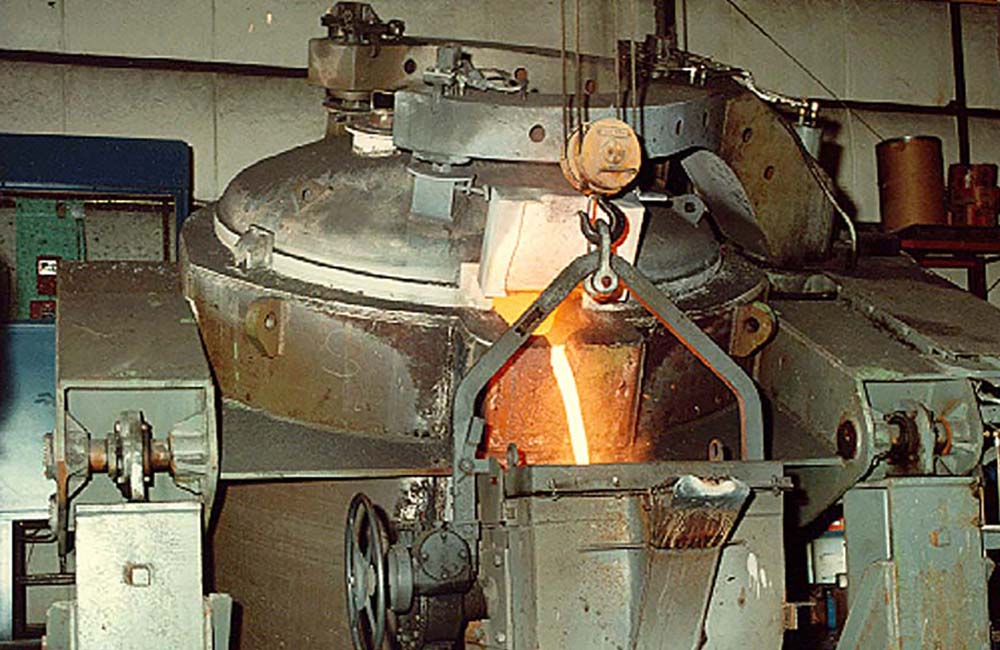

Channel Holding Furnaces

Inductotherm Channel Holding Furnaces combine high productivity with economical operation and provide a continuous supply of ready-to-pour metal 24 hours a day. Select channel furnaces when high production operations need a large throughput of metal, few alloy changes are needed, and when you need the holding capacity to shift melting operations to take advantage of off-peak energy costs or the lowest energy consumption in multi-shift operations.

Features

Channel Holding Furnaces are capable of holding large quantities of metal at low holding power levels for extended periods of time. Metal stored in the Channel Holding Furnace can be steadily fed from a cupola or batch fed from a coreless furnace and tapped into ladles in accordance with any particular production schedule. Melting can take place during off-peak energy demand periods and then be stored in the Channel Holding Furnace and tapped for production during on-peak hours. Using a variety of efficient inductors, Channel Holding Furnaces operate year after year with minimal maintenance. A full 80 percent of the vessel capacity can be used in order to maximize the volume available for either continuous or batch duplexing.

Tech Specs

| Capacities | Up to 170 Metric Tons [187 Short Tons] |

| Contact Inductotherm for Custom Solutions | |

| Standard Features | Partial or Full Stanchion Frame and Tilt Cylinders |

| Easy Access Slag Door | |

| High-Conductivity Copper Coil Tubing | |

| Spherical Dished Bottom | |

| Hydraulic Cylinders | |

| Water-Cooled Inductors | |

| Dyna-Flow™ Inductor Systems | |

| kWh Counter | |

| Water Cooling Drain Monitor | |

| Spouts Located Outside or Inside the Stanchion Pivots | |

| Optional Features | PLC Control and Management Systems |

| Various Back Platform Configurations | |

| Lip Pour Design | |

| Teapot Design Siphon Configurations | |

| Underpour Design Siphon Configurations | |

| Access Ports | |

| Lid Working Platform | |

| Lift/Swing Lid | |

| Load Cells | |

| Launders | |

| Lining Monitoring | |

| Fume Ring | |

| Inert Atmosphere Purge | |

| Frame Indexing | |

| Inductor Types | Single Loop, Water-Cooled or Air-Cooled |

| Twin Loop, Water-Cooled or Air-Cooled | |

| Spout Configurations | Single/Front |

| Duplexing/Front | |

| Duplexing/Side | |

| Slag Spout | |

| Factory Tested | Critical Components |