ACR Copper Tube Annealer

The Inductoheat ACR Copper Tube Annealing system is a complete line solution designed for ease of use, efficient operation and high speed production. This high speed annealing system can process up to 600 m/minute in a “Basket to Basket application or up to 200 m/minute when going from “Basket to Box.”

Features

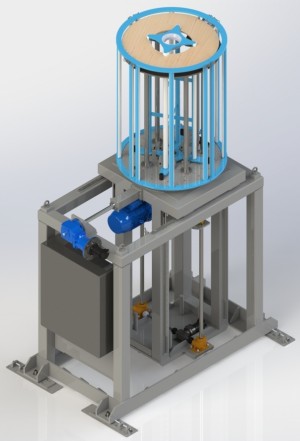

- Complete systems with full line mechanics

- Mechanical systems are designed for ease of operation and maintenance

- Central electrical control system ensures power input is continually varied to suit the corresponding line speed

- Electrical control system features ‘HMI’ interface for ease of operation and allows programming of a multitude of tube sizes

- Solid state inverters operating in both medium and high frequencies

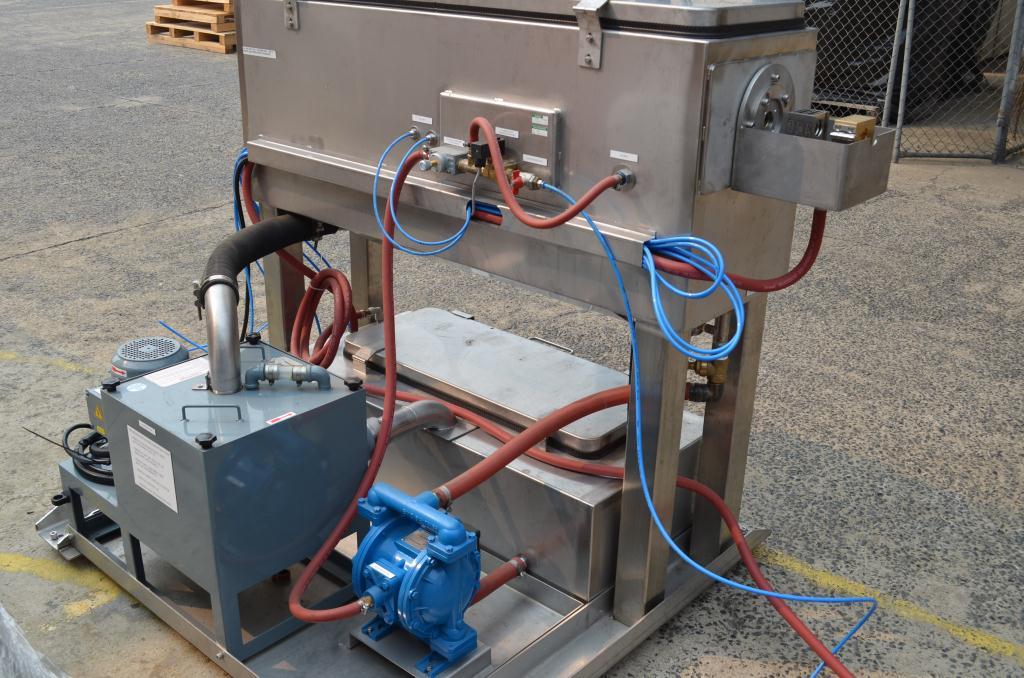

- Power supplies are water cooled by means of a closed loop recirculating system

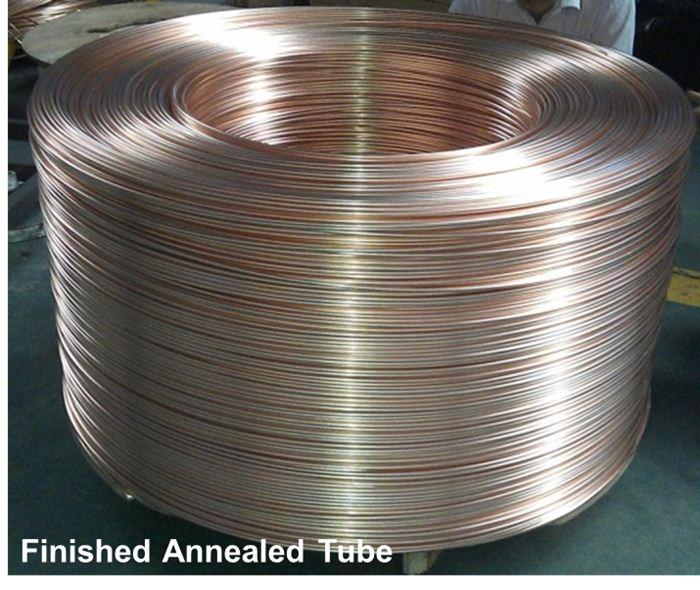

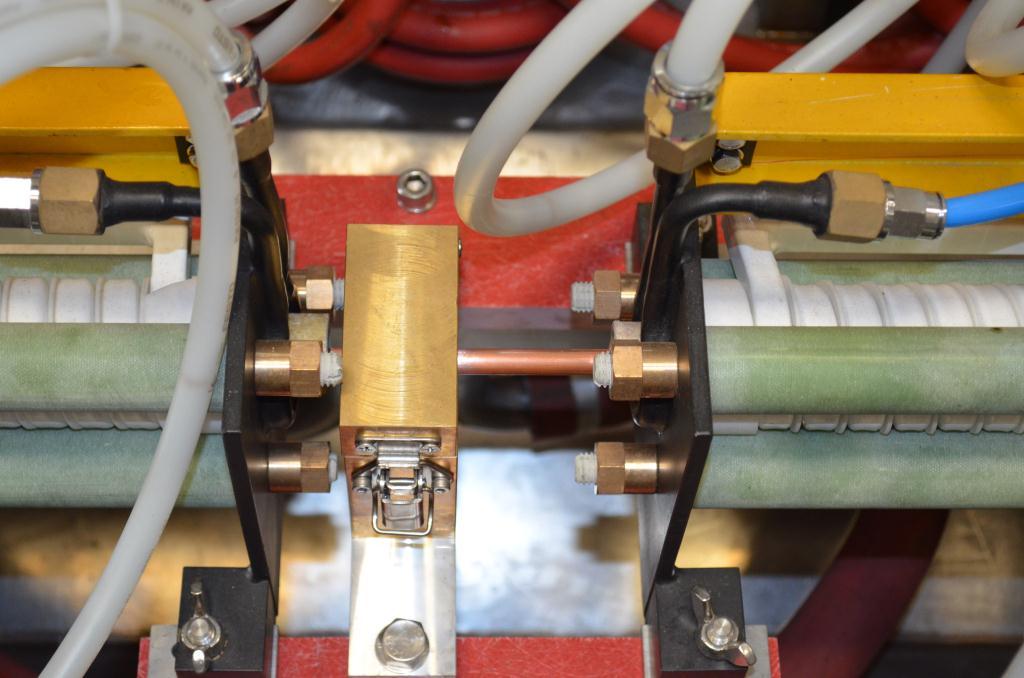

- Inductor coil line designed to induction anneal copper tube under a reducing atmosphere to produce a bright annealed finish both inside and outside

- Dwell and quench zones are designed to ensure the copper tube is first held at the correct temperature to obtain full grain uniformity, before being rapidly cooled at full line speed for maximum productivity

- High speed induction heating for annealing at line speeds of up to 600 meters per minute with minimal operator interface

Tech Specs

Basket to Basket

Part Name: ‘ACR’ Copper Tube

Material: Deoxidized Copper

Annealing Temperature: 700 C

Power Supply; 1200 kW 6.0 kHz ‘VIP’

Tube Diameter: 7.0 mm to 12.7 mm

Max Line Speed: 600 m/Minute

Basket to Box

Part Name: ‘ACR’ Copper Tube

Material: Deoxidized Copper

Annealing Temperature: 700 C

Power Supply: 300 kW 30.0 kHz ‘SP16’

Tube Diameter: 5.0 mm to 9.52 mm

Max Line Speed: 200 m/Minute