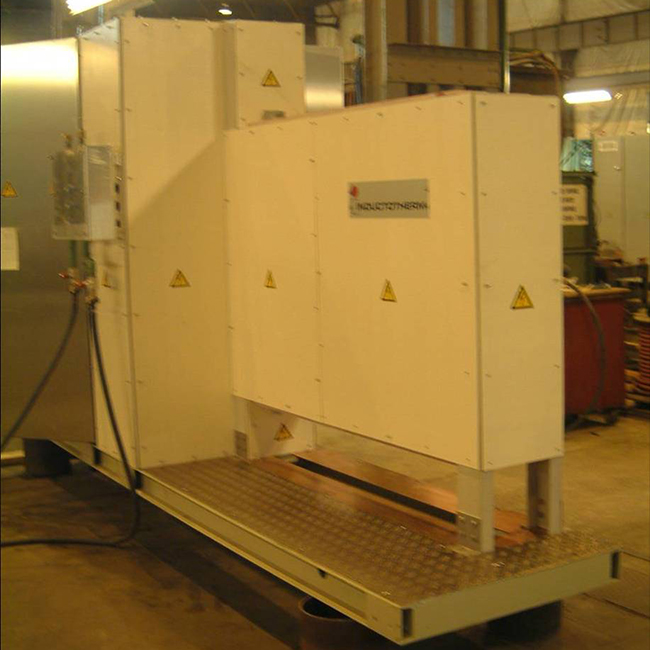

Tin Reflow Systems

Modern tinning lines use high-frequency STATITRON™ inverters for this application. The main advantages of these inverters in comparison with the old vacuum tube generator are: better electrical efficiency, safer and easier maintenance, and reduced dimensions. Tin Reflow Systems using the new transistor inverters have even better efficiency than conduction type heating systems.

Features

Tin Reflow Systems are critical to creating tinplate which is essentially a light-gauge steel coated with tin on both sides. After the tin has been electrolytically deposited on the strip, it is momentarily melted resulting in a nonporous iron-tin layer. This layer improves weldability and mechanical and corrosion resistance. Our high-frequency STATITRON™ inverter technology permits rapid melting of the tin layer at high efficiency (approximately 80 percent) thus reducing the overall cost to produce this product. Inductotherm Tin Reflow Systems powered by the high-frequency STATITRON™ inverter can be installed in the following situations:

- To increase the capacity of an existing tinning line

- To replace an existing outdated vacuum tube generator with a transistorized inverter

- To revamp old production lines by completely replacing the conduction heating system

- To provide 100 percent heating in new production lines

Tech Specs

| Capacities | Up to 4,000 Kilowatts |

| Contact Inductotherm for Custom Solutions | |

| Standard Features | High Frequency |

| High Efficiency | |

| Factory Tested | Critical Components |