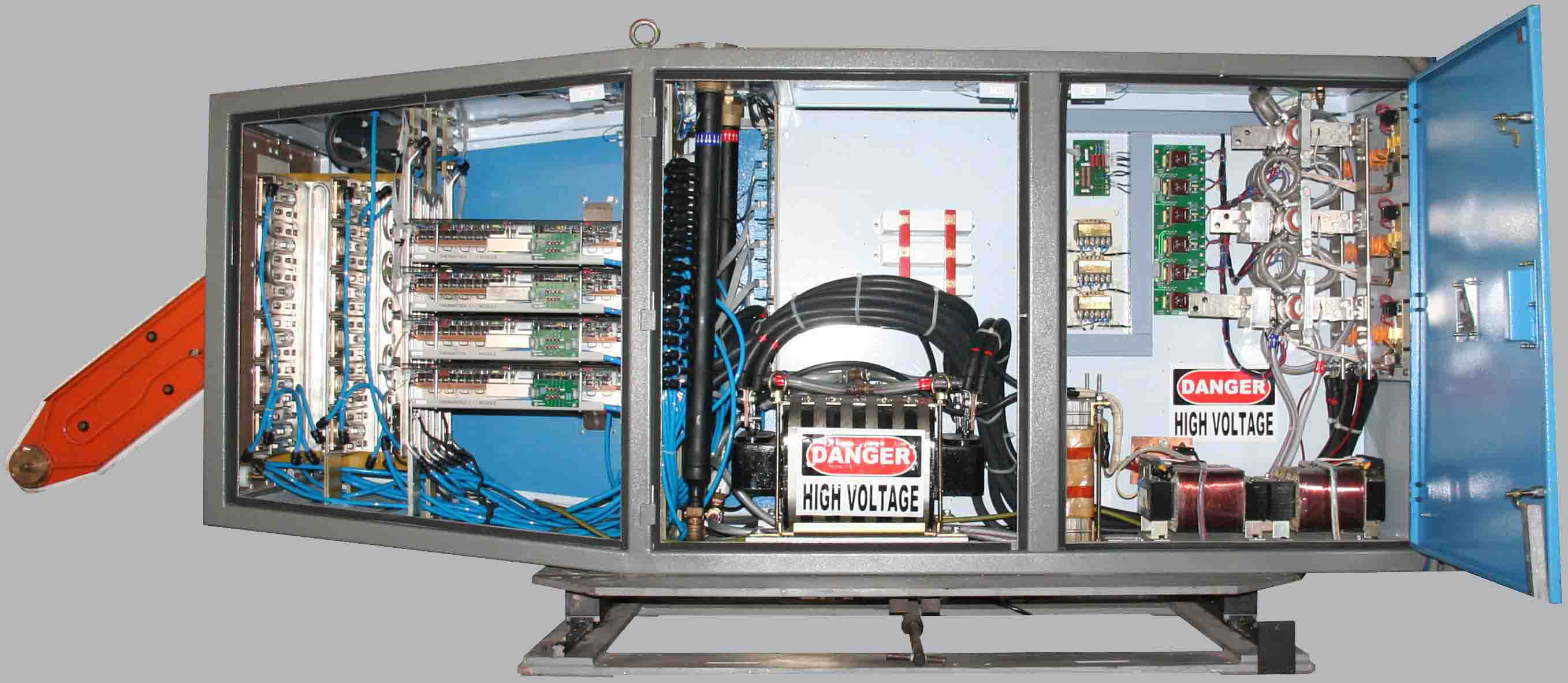

Compact Welder

Perfect for low power applications and limited diameter tube mills, the Thermatool™ Compact HF Welder is a good fit when capital expenditures are limited. This simplified and compact design combines the traditional DC power supply into the RF Generator cabinet, making this welder the logical choice for low cost installations. The Compact welder is ideal for quick retrofitting on existing mills when replacing older vacuum tube welders. All the reliability of a classic Thermatool™ Solid-State HF Welder, with a small footprint.

Features

- Compact cabinet design combines DC Rectifier and RF Generator all in one (minimizes installation time and expense)

- Available in contact or induction models

- Isolation transformer, circuit breaker and primary line disconnect come in a separate air-cooled enclosure

- Nominal output frequency of 300 kHz

- Simplified circuit includes limited electronically load matched output

- Excellent low weld power output stability and regulation for welding at mill jog speeds (as low as 1% power)

- Power set-point maintained within 0.5%

- High efficiency rating of at least 85%

- Short-circuit tolerant current fed technology ensures reliable operation through coil arc-overs

- PLC based control

- Touchscreen operator interface

- PLC based speed/power control simplifies operation and significantly reduces scrap through accurate control of weld power in relation to mill speed at start-up and ramp down

Tech Specs

Standard Power Ratings: 50kW-300kW

Nominal Frequency: 300kHz

380, 480, 575 V at 50/60 Hz input compatible

50 kW HF Module using MOSFETs

Tooling

Tooling

Genuine Thermatool™ tooling including induction coils and impeders ensure full weld power output and reliable operation. Thermatool™ induction coils are designed per application for long-life and optimized matching between the welder and the range of loads presented by different diameter and wall thickness combinations produced on a mill. Impeders and impeder booster pumps are available to minimize power used during welding and increase the efficiency of the welding process by ensuring that power is directed down the vee.